1.Qualified tensile strength and hardness

2.Approved by ISO9001, CE, SGS, BV, Form-E, CO , MTC Certificates

3. Quick delivery and standard wooden exporting package.

4. Low MOQ and Flexible Production Ability.

5.Support payment with T/T, L/C , paypal, kunlun bank, etc.

6. OEM and ODM, welcome customers to visit our factory for better understanding;

7. Our factory provide steel products with competitive price and reliable quality;

8. Value friendship and trustworthy, devote to provide long-term service to our distinguished customers.

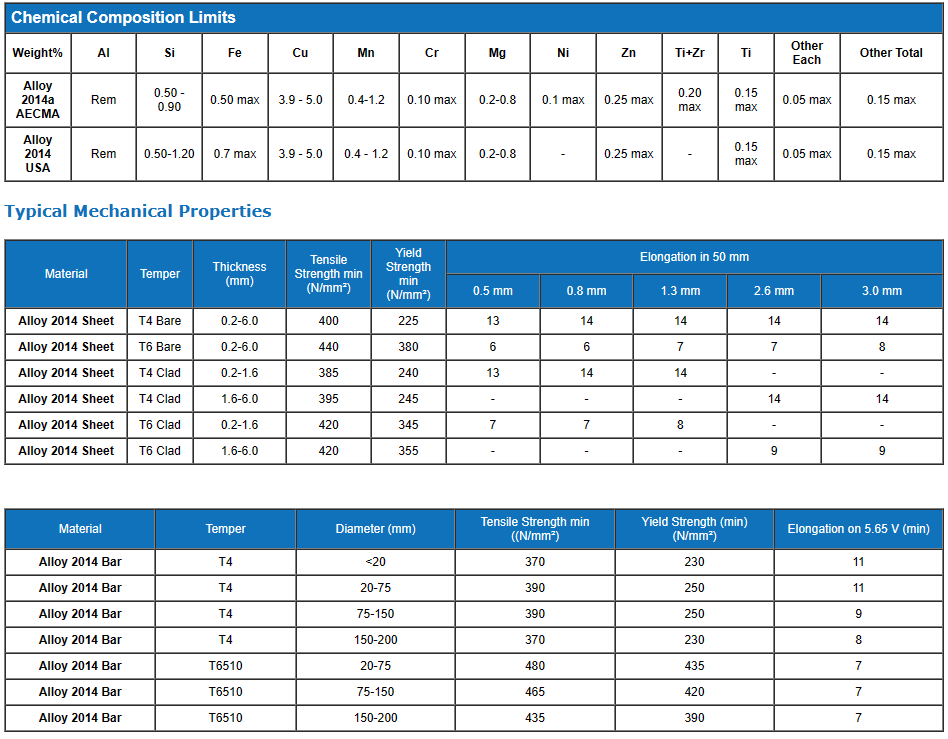

The chemical composition of Aluminum Alloy 2014 falls within the following parameters:

Cu 3.9-5.0%

Mn .40-1.2%

Mg .20-.80%

Fe .50%

Si .50-.90%

Zn .25%

Cr .10%

Ti .15%

Features

For customers who need an aluminum product with strength, machinability and welding capabilities, Aluminum Alloy 2014 is an excellent option. It is a precipitation hardening alloy that maintains strength after heat treatment, which should be performed at 935°F and followed by a water quench.

Aluminum Alloy 2014 can be machined best in the annealed condition. Any welding should be conducted using inert gas consumable electrode arc methods with alloy 2014 or alloy 2017 filler rods. When welding, it is important to arrange fixturing for minimum strain to avoid cracking.

Application

Construction/Indutry/Building/Chemical/Auto

Aircraft structures

Truck Frames

Military vehicles

Aerospace fittings

Structural applications

High strength structural components

Get real-time quotes

Interested? Leave your contact details.

Get real-time quotes

Interested? Leave your contact details.