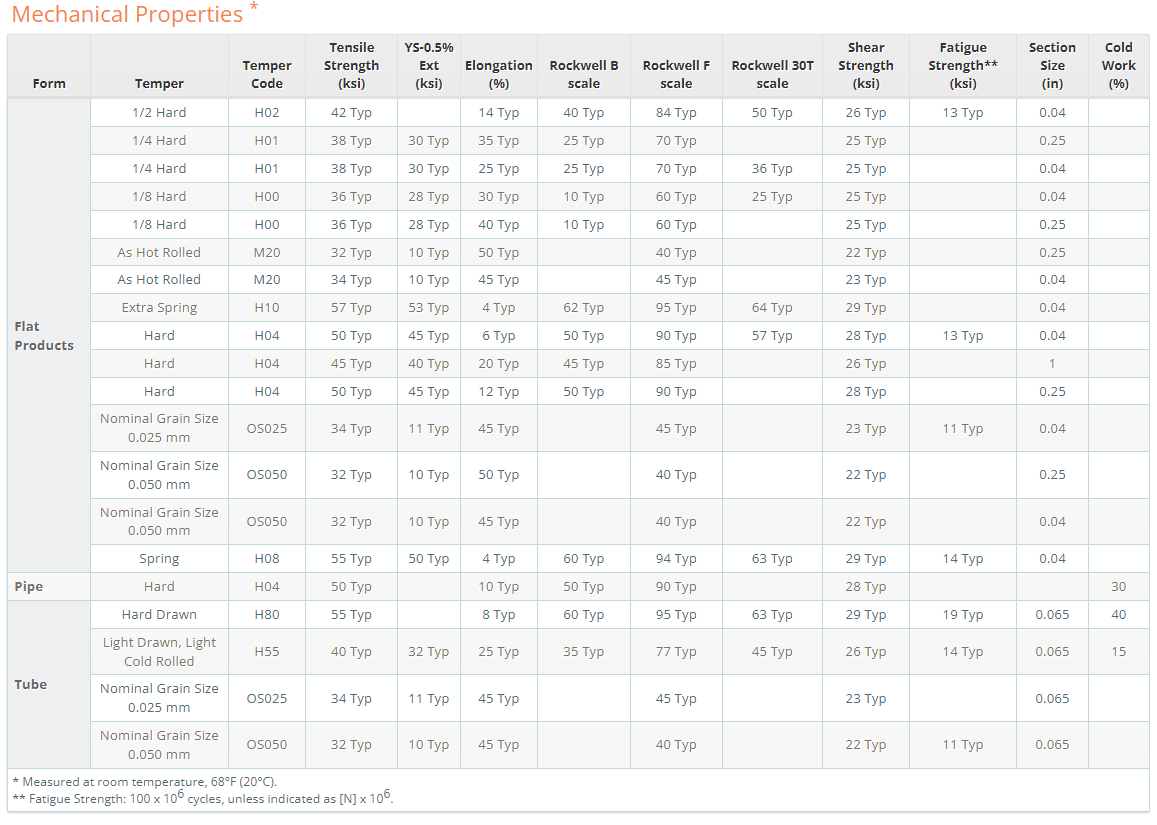

1.Qualified tensile strength and hardness

2.Approved by ISO9001, CE, SGS, BV, Form-E, CO , MTC Certificates

3. Quick delivery and standard wooden exporting package.

4. Low MOQ and Flexible Production Ability.

5.Support payment with T/T, L/C , paypal, kunlun bank, etc.

6. OEM and ODM, welcome customers to visit our factory for better understanding;

7. Our factory provide steel products with competitive price and reliable quality;

8. Value friendship and trustworthy, devote to provide long-term service to our distinguished customers.

C12200 copper pipe is a high-purity oxygen-free copper material with good corrosion resistance and easy processing. C122 is commercially pure copper that has been phosphorus deoxidized, leaving a relatively high residual phosphorus content. Copper Alloy 122 is less susceptible to hydrogen embrittlement but has relatively low electrical conductivity due to the phosphorus content.

Composition: Copper C11000 pipes are a high-purity copper alloy with a minimum copper content of 99.90%, while Copper C12200 pipes are a brass alloy containing copper and zinc with a copper content of approximately 99.9%.

Strength: Copper C12200 pipes have higher tensile strength and yield strength compared to Copper C11000 pipes. This makes them more suitable for applications requiring higher mechanical strength, such as fasteners and connectors.

Corrosion Resistance: Both Copper C11000 and C12200 pipes are highly resistant to corrosion. However, Copper C11000 pipes offer better resistance to corrosion in seawater and marine environments due to their high copper content.

Electrical Conductivity: Copper C11000 pipes have the highest electrical conductivity of all copper alloys, making them an excellent choice for electrical applications that require high conductivity.

Thermal Conductivity: Both Copper C11000 and C12200 pipes have excellent thermal conductivity. However, Copper C11000 pipes have slightly higher thermal conductivity than C12200 pipes.

Fabrication: Both Copper C11000 and C12200 pipes are easy to machine and fabricate. However, Copper C12200 pipes are more easily formed due to their higher zinc content.

Application

Construction/Indutry/Building/Chemical/Auto

application fields include in the electronics industry: used in electronic devices and circuit boards, such as connecting wires, insulators and wires; in the refrigeration and air-conditioning industry, used in the manufacture of refrigeration pipes, heat exchangers, evaporators and other cooling equipment; In the automotive industry, it is used for radiator ducts, fan components and braking systems of car engines; in the construction industry, it can be used as pipes and fittings inside buildings, such as water supply pipes and heating systems.

Get real-time quotes

Interested? Leave your contact details.

Get real-time quotes

Interested? Leave your contact details.