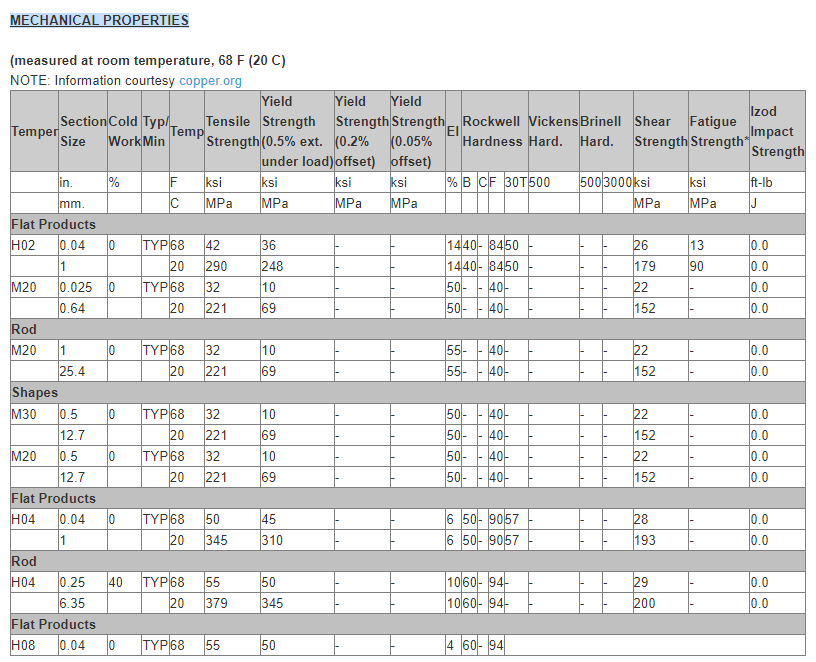

1.Qualified tensile strength and hardness

2.Approved by ISO9001, CE, SGS, BV, Form-E, CO , MTC Certificates

3. Quick delivery and standard wooden exporting package.

4. Low MOQ and Flexible Production Ability.

5.Support payment with T/T, L/C , paypal, kunlun bank, etc.

6. OEM and ODM, welcome customers to visit our factory for better understanding;

7. Our factory provide steel products with competitive price and reliable quality;

8. Value friendship and trustworthy, devote to provide long-term service to our distinguished customers.

C11000 Electrolytic Tough Pitch (ETP) Copper is known for its high electrical and thermal conductivity, good corrosion resistance and solderability. C11000 copper is used for welding fixtures, anodes, bus strip in electrical power installations, ground straps, commutators and current-carrying hardware. Its inherent fabrication qualities readily permit it to be bent, soldered, drilled, peened, riveted and formed to fit almost any design specification. This copper has excellent hot workability.

CHEMICAL COMPOSITION(%max., unless shown as range or min.)

Features

High Electrical Conductivity: C11000 copper is known for its excellent electrical conductivity, which is among the highest of all pure metals. This property makes it ideal for applications where efficient electrical transmission is critical, such as in electrical wiring, power distribution systems, busstrips, and electrical contacts.

Good Thermal Conductivity: Besides electrical conductivity, C11000 copper also exhibits good thermal conductivity. This feature is beneficial in applications where effective heat dissipation or thermal management is required, such as in heat exchangers, cooling systems, and industrial machinery.

Corrosion Resistance: Copper, including C11000, naturally forms a protective oxide layer when exposed to air, which enhances its resistance to corrosion. This makes C11000 copper strips suitable for use in environments where exposure to moisture, humidity, or corrosive elements is a concern, such as in plumbing systems or marine applications.

Malleability and Ductility: C11000 copper is highly malleable and ductile, meaning it can be easily formed, bent, and shaped without cracking or weakening. This property allows for easy fabrication into various forms, including strips, rods, strips, and custom shapes, to meet specific application requirements.

Ease of Joining: C11000 copper strips can be welded, brazed, soldered, or mechanically joined using standard techniques, facilitating their integration into complex assemblies or structures.

Antimicrobial Properties: Copper, including C11000, possesses inherent antimicrobial properties, which inhibit the growth of bacteria, viruses, and fungi on its surface. This property is increasingly recognized and utilized in applications requiring hygiene and sanitation, such as in healthcare facilities and food processing equipment.

Recyclability: Copper is highly recyclable without any loss of its inherent properties, making C11000 copper strips an environmentally sustainable choice.

Application

Construction/Indutry/Building/Chemical/Auto

Building Fronts, Gutters, Skylight Frames, Roofing, Flashing, Downspouts, Spouting

Pressure Vessels, Chemical Process Equipment, Chlorine Cells, Chimney Cap Screens, Heat Exchangers, Printing Rolls, Anodes, Rotating Bands, Kettles, Pans, Vats, Road Bed Expansion Plates

Get real-time quotes

Interested? Leave your contact details.

Get real-time quotes

Interested? Leave your contact details.