1.Qualified tensile strength and hardness

2.Approved by ISO9001, CE, SGS, BV, Form-E, CO , MTC Certificates

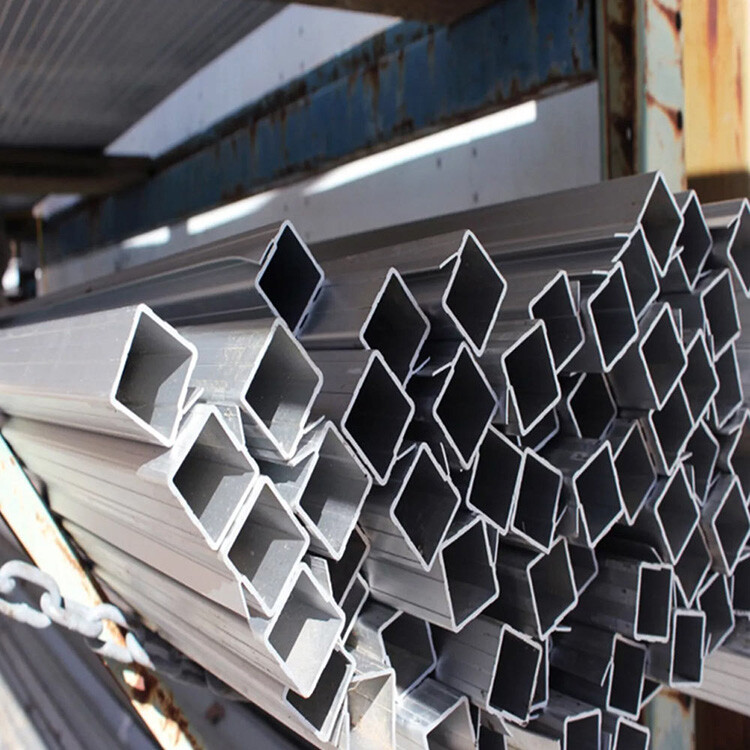

3. Quick delivery and standard wooden exporting package.

4. Low MOQ and Flexible Production Ability.

5.Support payment with T/T, L/C , paypal, kunlun bank, etc.

6. OEM and ODM, welcome customers to visit our factory for better understanding;

7. Our factory provide steel products with competitive price and reliable quality;

8. Value friendship and trustworthy, devote to provide long-term service to our distinguished customers.

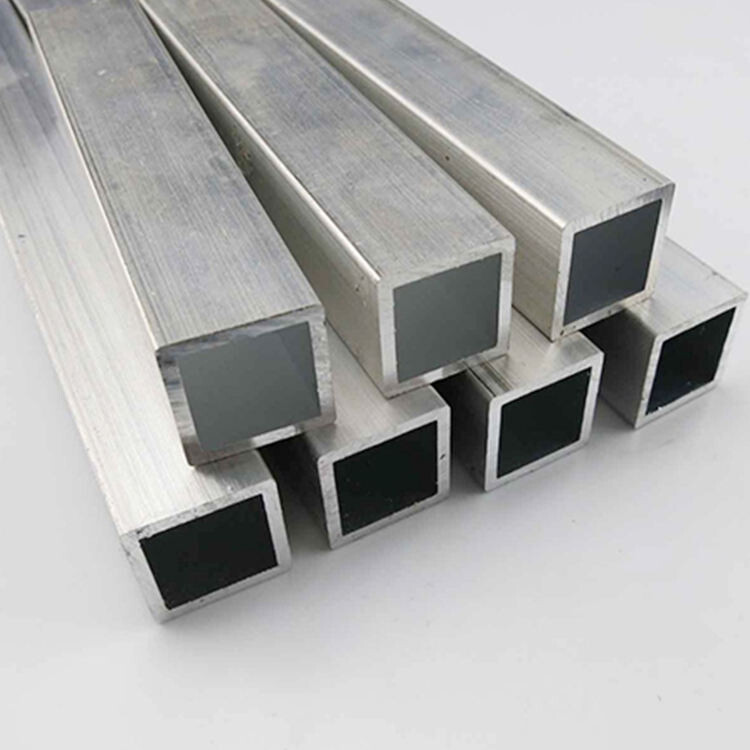

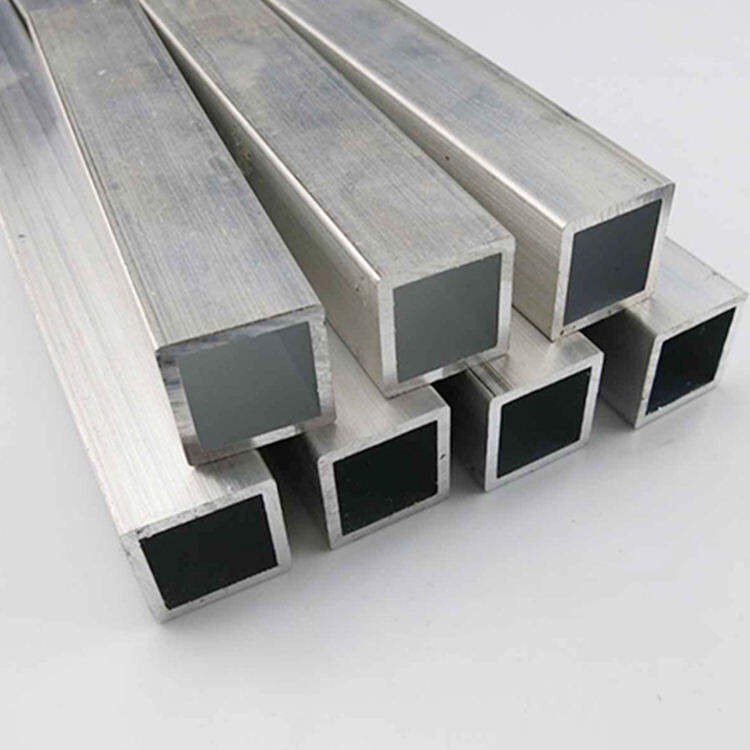

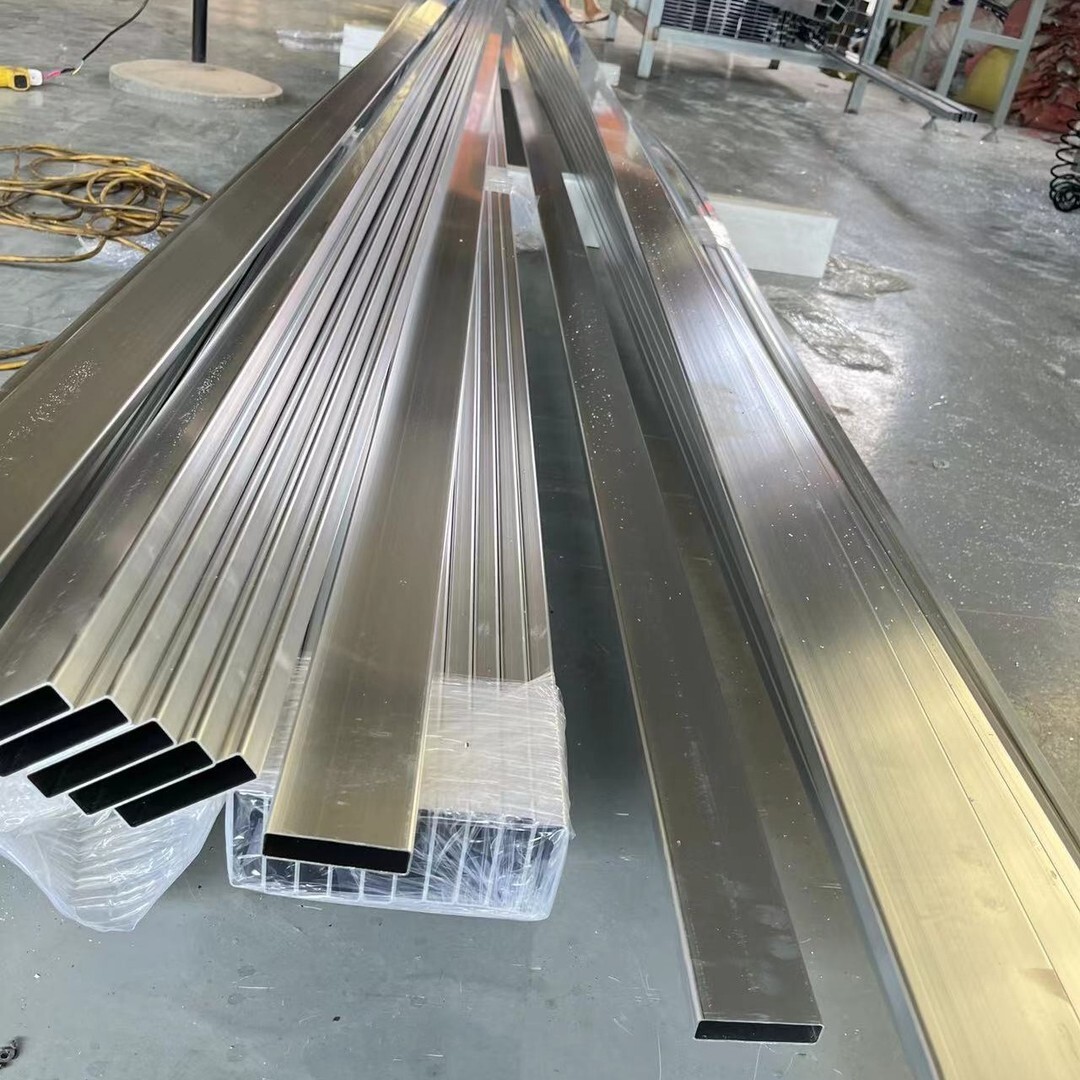

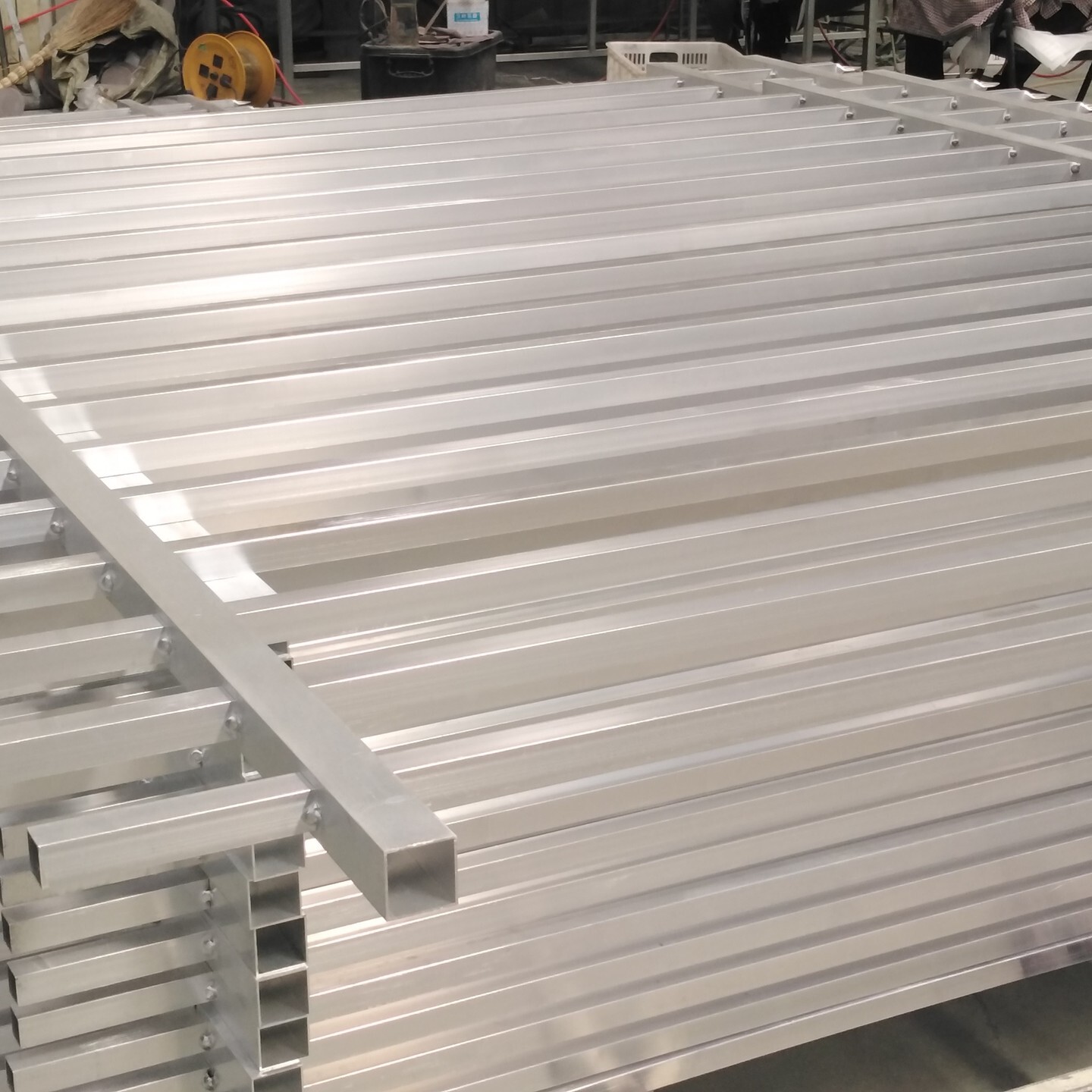

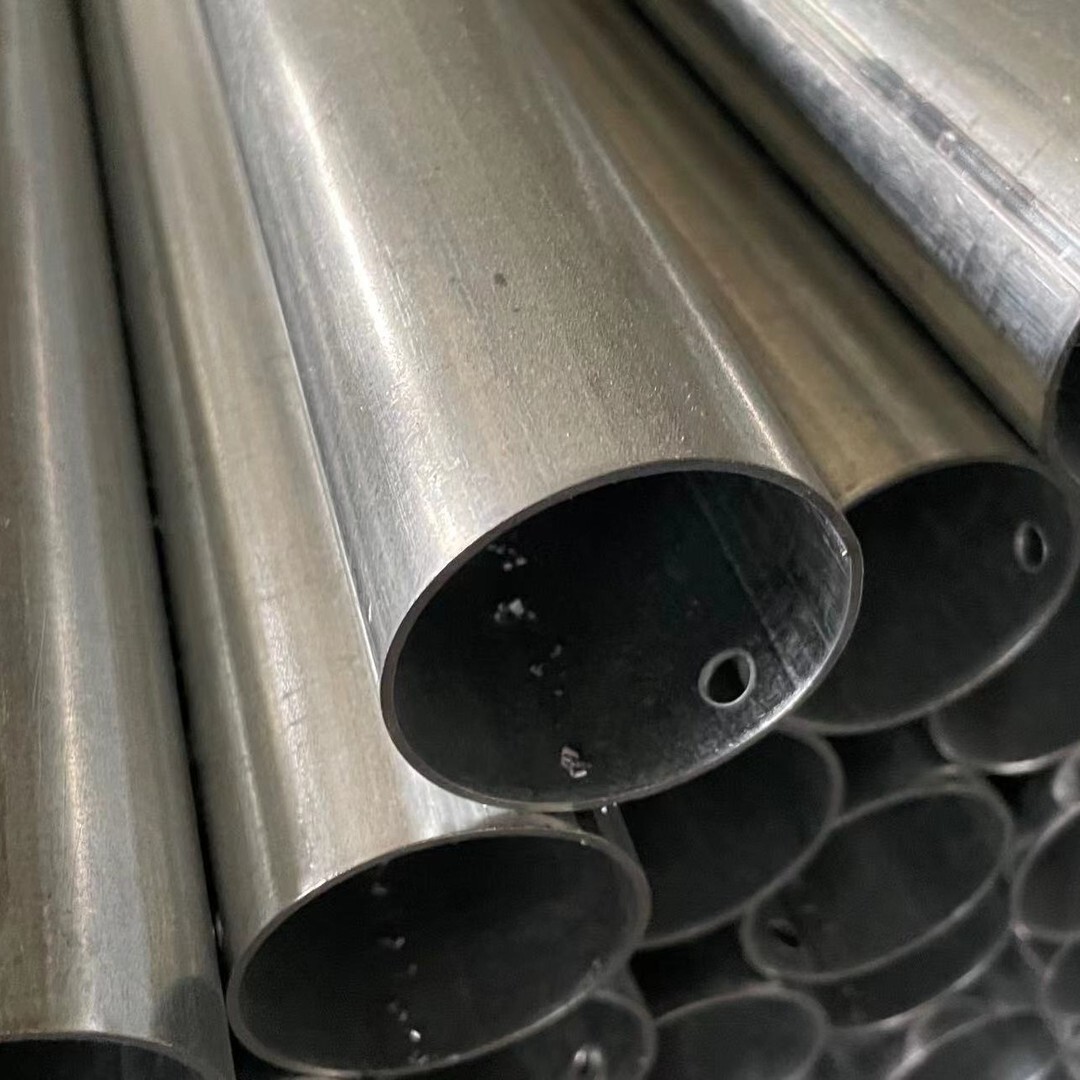

3004 aluminium alloy is an alloy in the wrought aluminium-manganese alloys family (3000 or 3xxx series). It is similar to the 3003 alloy, except for the addition of approximately 1% magnesium. It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose alloy with moderate strength, good workability, and good corrosion resistance. It is commonly rolled and extruded, but typically not forged. As a wrought alloy, it is not used in casting.

Features

Machinability

Aluminium / Aluminum 3004 alloy has good machinability in the hard temper. Oil lubricant is used for performing machining operations.

Forming

Aluminium / Aluminum 3004 alloy can be formed using conventional hot working or cold working methods.

Welding

The Aluminium / Aluminum 3004 alloy can be welded using TIG or MIG welding techniques.

Heat treatment

Aluminium / Aluminum 3004 alloy is a non-heat treatable alloy.

Forging

Aluminium / Aluminum 3004 alloy is forged at temperatures ranging from 372 to 510°C (700 to 950°F).

Hot Working

Aluminium / Aluminum 3004 alloy is hot worked at 260 to 483°C (500 to 900°F).

Cold Working

Aluminium / Aluminum 3004 alloy can be cold worked up to 75% reduction of area using conventional techniques. This process should be followed by annealing if it is cold worked beyond 75% reduction of area.

Annealing

Aluminium / Aluminum 3004 alloy is annealed at 344°C (650°F) followed by cooling in air.

Hardening

Aluminium / Aluminum 3004 alloy can be annealed by cold working.

Applications

Aluminium / Aluminum 3004 alloy is used in sheet metal work. It is also used in manufacturing storage tanks.

Application

Construction/Indutry/Building/Chemical/Auto

The alloy 3004 is commonly used in the making of beverage cans. It was developed to satisfy the need for thinner gauges in can-stock, and thereby to some extent replaced its predecessor 3003 alloy in the making of beverage cans. Can-stock can be made thinner due to the addition of 1% magnesium, which contributes in solid solution strengthening.

Get real-time quotes

Interested? Leave your contact details.

Get real-time quotes

Interested? Leave your contact details.