1.Qualified tensile strength and hardness

2.Approved by ISO9001, CE, SGS, BV, Form-E, CO , MTC Certificates

3. Quick delivery and standard wooden exporting package.

4. Low MOQ and Flexible Production Ability.

5.Support payment with T/T, L/C , paypal, kunlun bank, etc.

6. OEM and ODM, welcome customers to visit our factory for better understanding;

7. Our factory provide steel products with competitive price and reliable quality;

8. Value friendship and trustworthy, devote to provide long-term service to our distinguished customers.

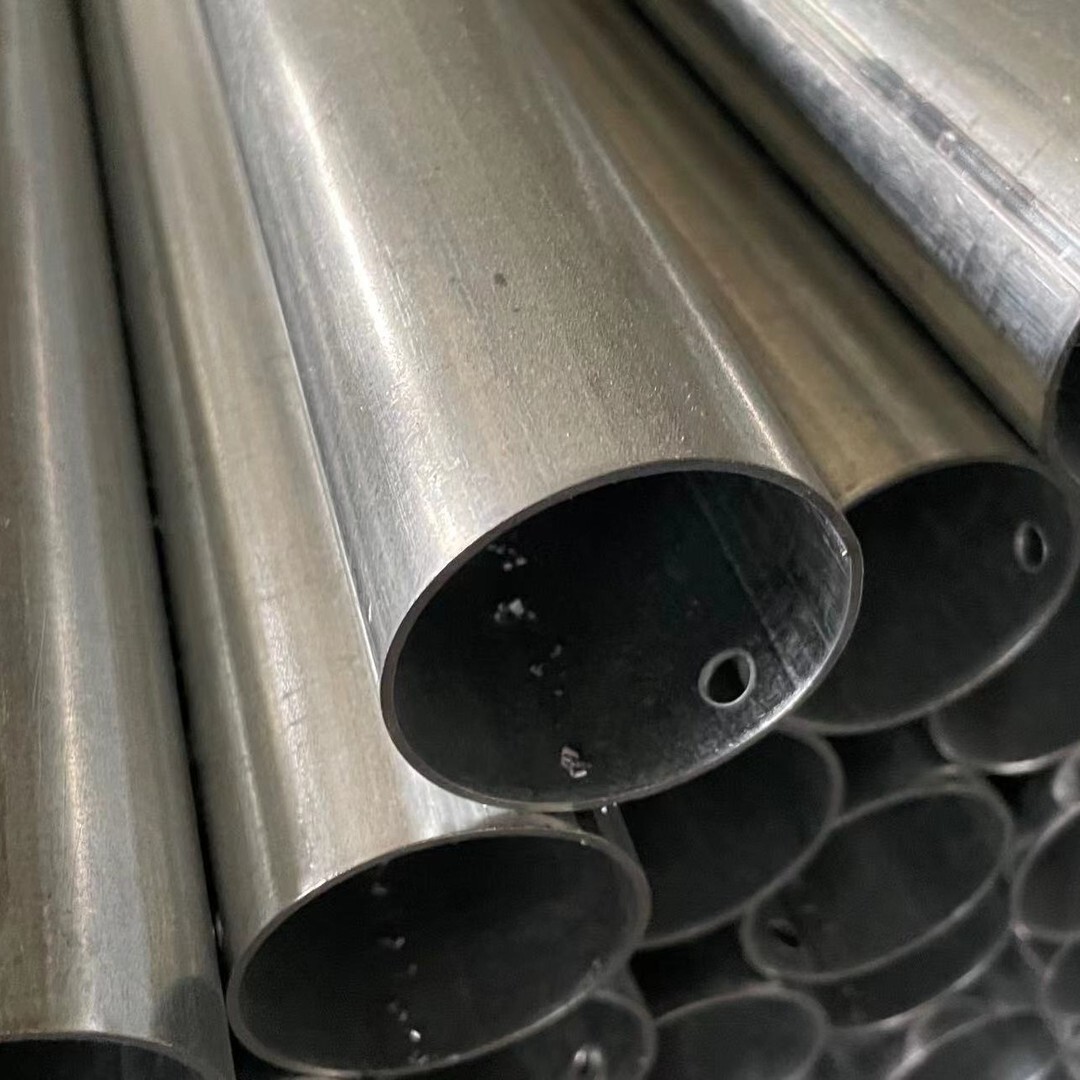

4007 aluminum is a 4000-series aluminum alloy. The main alloying addition is silicon. 4007 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-4007. Additionally, the EN chemical designation is AlSi1,5Mn. And the UNS number is A94007.

It originally received its standard designation in 1978.

The properties of 4007 aluminum include three common variations. This page shows summary ranges across all of them. For more specific values, follow the links immediately below. The graph pipes on the material properties cards further below compare 4007 aluminum to: 4000-series alloys (top), all aluminum alloys (middle), and the entire database (bottom). A full pipe means this is the highest value in the relevant set. A half-full pipe means it's 50% of the highest, and so on.

Chemical element metric

Aluminum 94 – 97.6 %

Chromium, Cr 0.05 – 0.25 %

Cobalt <= 0.05 %

Copper, copper <= 0.20 %

Iron, Iron 0.40 – 1.0 %

Magnesium, Magnesium <= 0.20 %

Manganese, Mn 0.80 – 1.5 %

Nickel, Nickel 0.15 – 0.70 %

Others, each <= 0.05 %

Others, total <= 0.15 %

Silicon, yes 1.0 – 1.7 %

Titanium, Ti <= 0.10 %

Zinc, Zinc <= 0.10 %

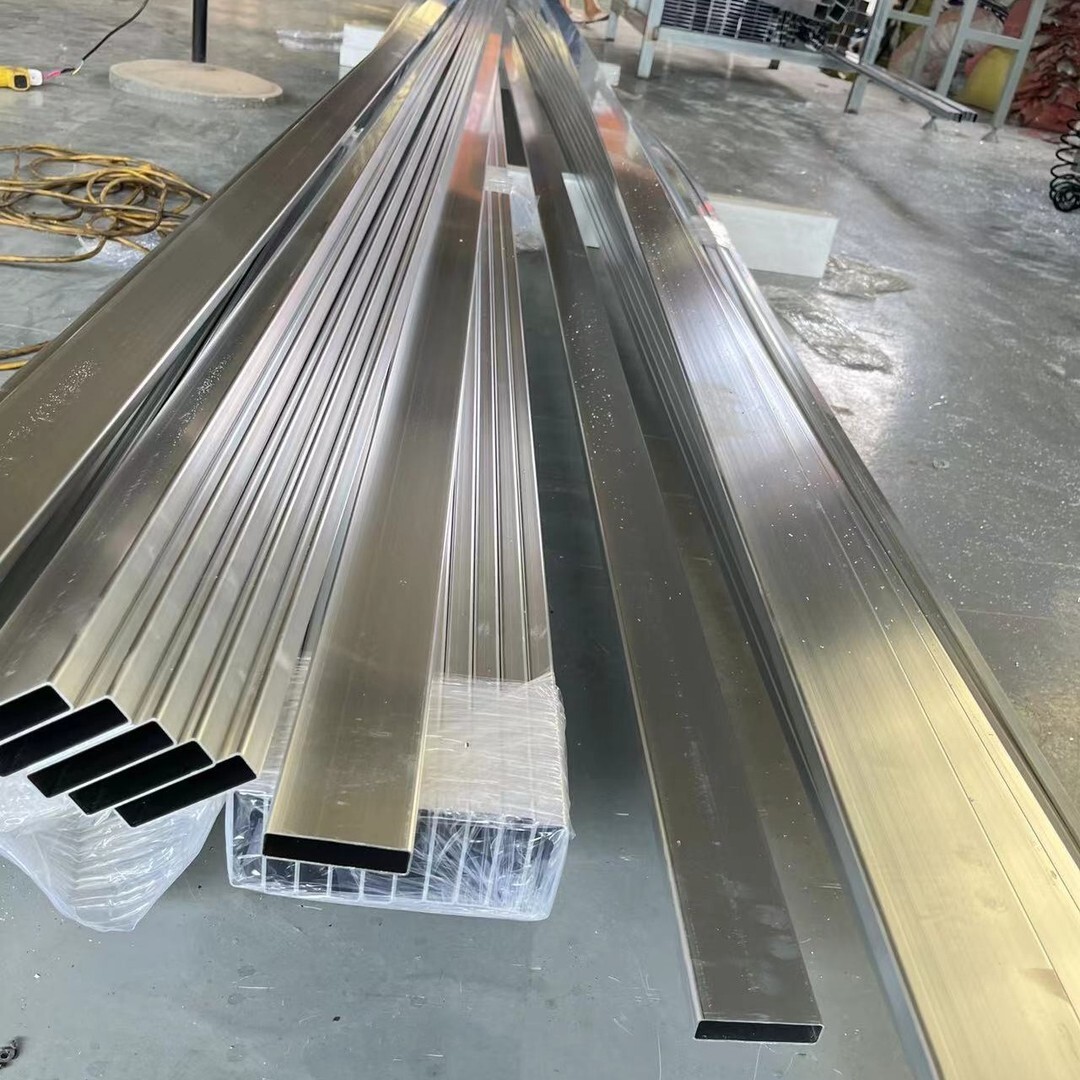

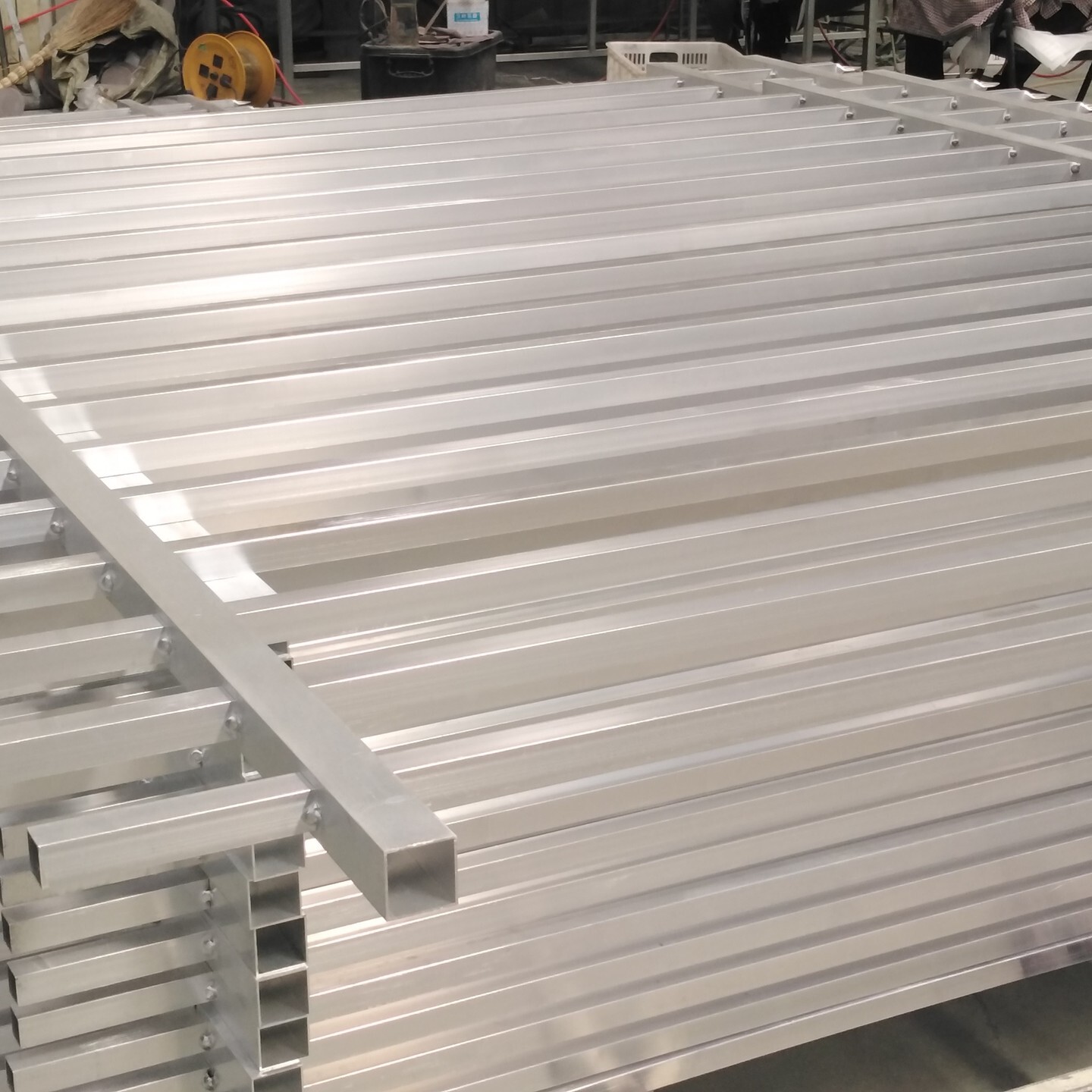

Features

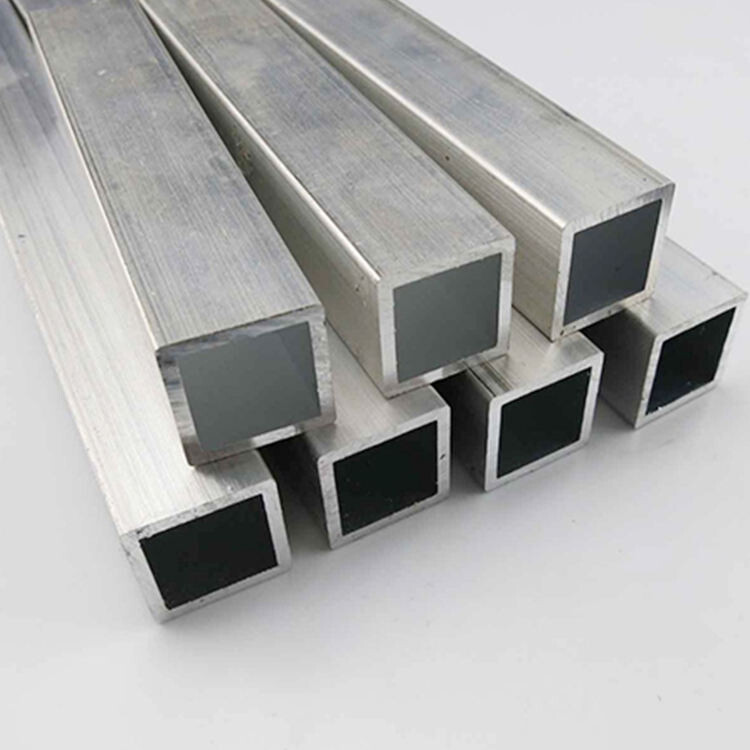

4047 Aluminum Alloy is an aluminum silicon brazing or filler alloy with good corrosion resistance. The main difference between alloy 4047 and it’s AL4043 counterpart is its higher silicon content. With 11-13% silicon, AL 4047 is generally used when high fluidity and reduced shrinkage and hot cracking is needed for specific repairs or manufacturing. Additionally, 4047 is suitable at elevated temperatures making it particularly useful in the automotive industry for parts and engine blocks.

Application

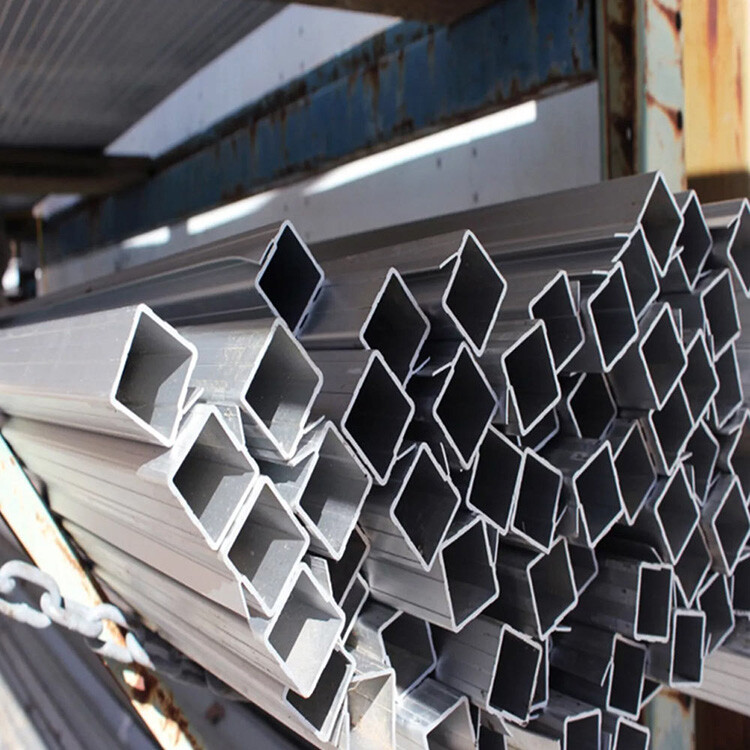

Construction/Indutry/Building/Chemical/Auto

4047 Aluminum pipe is used in a variety of applications including Liners, Laser Weld Covers for Microwave Integrated Circuits and other similar devices, Housing, joining material within the Aluminum family of alloys, Automotive, Engine Blocks, Welding Filler Wires, leak tight joints.

Get real-time quotes

Interested? Leave your contact details.

Get real-time quotes

Interested? Leave your contact details.